Overview: Supporting Scientific Innovation Through Smart Electrical Solutions

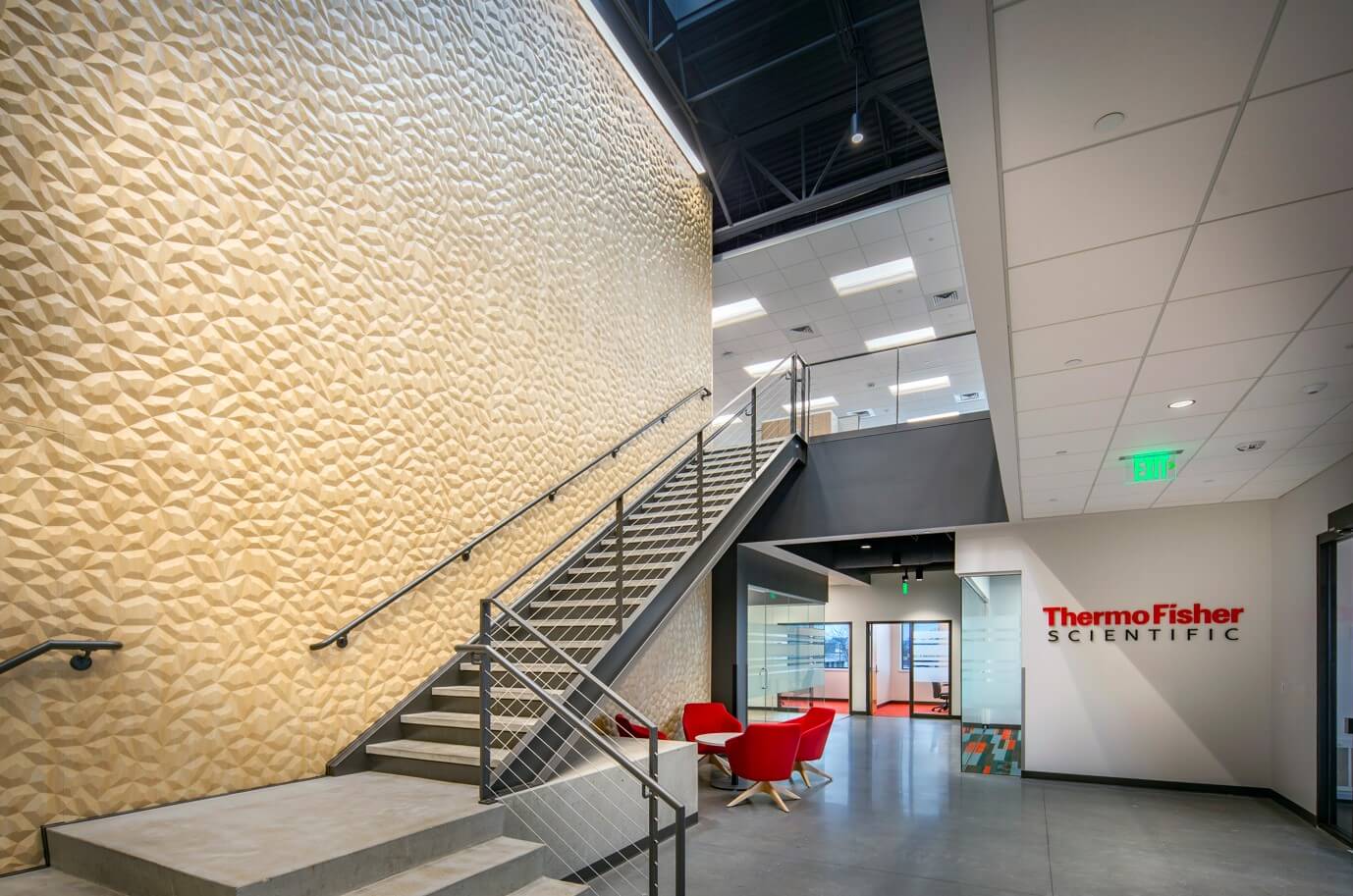

FTI partnered with Thermo Fisher Scientific on the expansion of their Pharmaceutical Product Development (PPD) Building 15 Liquid Chromatography-Mass Spectrometry (LCMS) and general laboratory in Middleton, Wisconsin. This 72,500-square-foot project enhances Thermo Fisher Scientific’s clinical development and laboratory services, improving their ability to deliver life-changing medicines.

FTI provided comprehensive end-to-end solutions, including design consulting, estimating, electrical installation, systems integration, engineering and off-site manufacturing. The project scope encompassed power distribution, lighting installation, branch power access control, structured cabling, fire alarms, monitoring systems, electrical metering and the installation of major equipment, such as an 800 KW generator and a 700 KVA UPS.

Challenges: Navigating Equipment Delays

The project faced significant challenges related to procurement, shipping and manufacturing delays for critical equipment such as generators and switchboards. These delays had the potential to disrupt the construction schedule and mechanical system start-up.

Solutions: Leveraging Technology & Teamwork to Stay on Track

FTI implemented innovative strategies to overcome these challenges, ensuring the project remained on schedule and under budget:

- Temporary Power Solutions: Developed and installed an 800-amp, 480-volt temporary service in collaboration with the local utility. This supported phased mechanical commissioning and avoided exceeding temporary service capacity.

- Off-Site Manufacturing: Leveraged manufacturing capabilities to produce 1,000 feet of wire mold and hundreds of prefabricated ceiling utility panels with outlets. This just-in-time delivery reduced material handling and improved onsite efficiency.

- Advanced Tools: Applied Trimble for precise onsite layouts and CS Alloy software for efficient commissioning.

- Renewable Integration: Recommissioned the building’s existing solar system into the new electrical distribution network to ensure optimal energy usage.

Close collaboration with the general contractor and proactive safety measures led to zero safety incidents throughout the project.

Results: On-Time, On-Budget

Despite procurement delays, the project was completed on time and under budget. The expansion boosts Thermo Fisher Scientific’s chemistry, manufacturing and control (CMC) analytical capabilities while creating up to 350 new career opportunities in the Middleton area.

The success of this project highlights FTI’s ability to deliver complex, innovative solutions while maintaining high standards of safety, quality and efficiency.